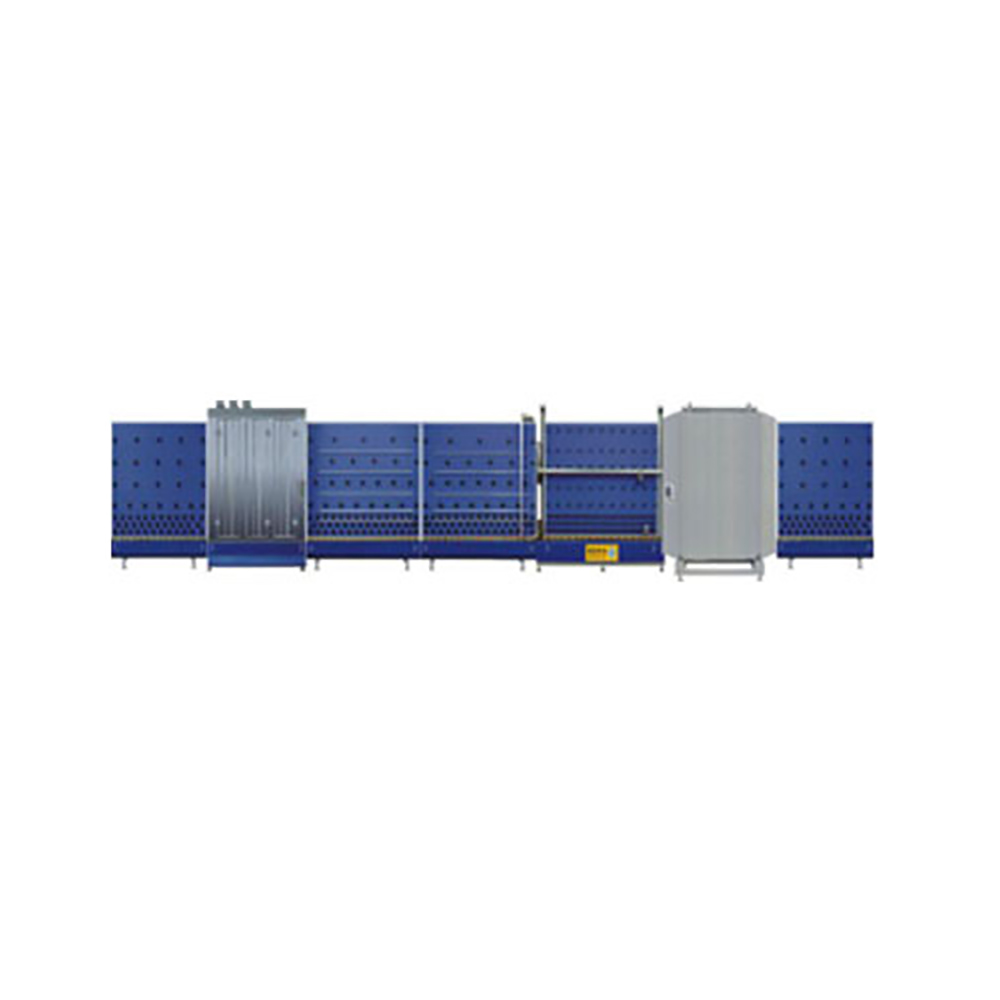

1. Fully automatic insulated glass production line (capable of producing LOW-E insulated glass)

2. Imported low-voltage electrical components and sensors are used, and PLC is used to automatically control the operation of the equipment throughout the process

3. Adopting imported vacuum generators and suction cups, the glass suction effect is better

4. The plate pressing section adopts a unique linear guide rail to fully ensure parallel pressing

5. According to different customer requirements, we can produce insulating glass of different sizes and three pieces (which is a special customization)

6. The cleaning area and water system are all made of stainless steel and corrosion-resistant materials, which are durable and long-lasting

7. Glass cleaning can be carried out continuously, and the machine automatically partitions the first and second pieces of glass, with zero waiting time for cleaning

8. Full distance automatic variable frequency speed regulation, saving labor waiting time and improving production efficiency

Technical parameters:

Input voltage: 380V 50Hz

Total power: 18Kw

Cleaning speed: 2-7m/min

Glass conveying speed: 22m/min

Minimum glass size: 450 * 500mm

Maximum glass size: 2500 * 1800mm

Cleaning glass thickness: 3-12m

Maximum thickness of insulated glass: 50mm

Compressed air: flow rate 0.8m ³/min, pressure 0.8Mpa

Water: Water conductivity ≤ 50us/cm

Dimensions: 22900mm * 1600mm * 2900mm

Total weight: 5500kg